Currently Empty: $0.00

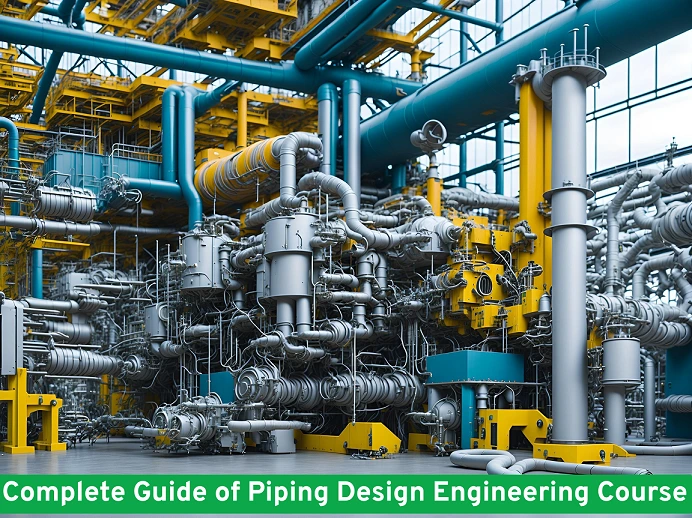

Piping Design Engineering

Complete Guide of Piping Design Engineering Course

Table of Content

1. Overview of Design Engineering for Piping

2. The Significance of Piping Design Engineering

3. Piping Design Engineering Career Opportunities

4. Who Needs to Enroll in a Course on Piping Design?

5. Competencies Needed by a Piping Design Engineer

6. Overview of the Piping Design Engineering Course

- Length of Course

- Qualifications Required

- Available Certifications

7. Fundamentals of Piping Systems;

- Materials and Specifications;

- Codes and Standards;

- Piping Components;

- Calculations for Pipe Sizing and Pressure Drop;

- Piping Layout and Design Considerations

- Pipe Supports and Hangers;

- Pipe Isometrics and Drawings;

- Stress Analysis and Flexibility;

- 3D Modeling and CAD Software;

- Safety and Maintenance

8. Piping Design Engineering Software

9. Sectors Needing Piping Design Engineers

10. Piping Design Engineering Job Roles and Pay

11. How to Pick the Best Course in Piping Design Engineering

12. Conclusion

- Overview of Design Engineering for Piping

The design, planning, and analysis of pipe systems utilized in sectors including oil and gas, chemical plants, power plants, water treatment facilities, and refineries are the main areas of study for the mechanical engineering specialty known as “piping design engineering.” The safe, effective, and economical conveyance of fluids (liquids, gases, and slurries) inside industrial facilities is guaranteed by a well-designed piping system.

This area is crucial to plant engineering and calls for an understanding of international codes and standards, fluid mechanics, materials, and stress analysis. - The Significance of Piping Design Engineering

Industrial enterprises rely on piping networks to facilitate the transportation of vital products. Failures, leaks, explosions, and excessive maintenance expenses can result from poorly built pipework. A well-designed piping system guarantees:

- Safety – Prevents mishaps caused by dangerous materials, high temperatures, and pressure.

- Efficiency: Assures low pressure loss and seamless operation.

- Cost savings: less wasteful maintenance and material waste are avoided.

- Compliance: Adheres to legal requirements and industry norms.

- Piping Design Engineering Career Opportunities

Worldwide, piping design engineers are highly sought after in a variety of industries. Numerous positions with alluring compensation packages are available on the employment market. Oil and gas, petrochemicals and refineries, power plants (thermal, nuclear, and renewable), chemical and fertilizer plants, pharmaceuticals, water treatment and distribution, and construction and infrastructure are a few of the businesses that employ piping engineers.

Following completion of a piping design engineering course, you can pursue the following roles:

CAD Designer (Piping), Project Engineer (Piping & Layout), Piping Consultant, Piping Design Engineer, Piping Layout Engineer, Piping Stress Engineer, and Pipeline Engineer - Who Needs to Enroll in a Course on Piping Design?

For mechanical engineers (diploma, B.Tech, or M.Tech), chemical engineers, civil engineers (working on construction and piping projects), industrial engineers, recent graduates hoping to break into the oil and gas, petrochemical, or power industries, and professionals seeking to advance their careers, a piping design engineering course is perfect. - Competencies Needed by a Piping Design Engineer

The following abilities are necessary to succeed in piping design engineering:

✔ Technical Knowledge: Knowledge of material science, thermodynamics, and fluid mechanics.

✔ Analytical Thinking: The capacity to evaluate layout efficiency, stress, and pressure drops.

✔ Software Proficiency: mastery of AutoCAD, PDMS, SP3D, Caesar II, and other programs.

✔ Attention to Detail: Making sure that industry standards and design rules are followed.

The ability to troubleshoot and optimize plumbing layouts is a key component of problem-solving skills. - Overview of the Piping Design Engineering Course

The purpose of a piping design course is to teach students both theoretical and practical aspects of piping system design and analysis.

Duration of the course usually three to six months (depending on whether it’s online, part-time, or full-time).

A degree or diploma in mechanical, civil, or chemical engineering is required for eligibility. It is also advantageous to have a basic understanding of engineering drawings and CAD software.

Available certifications include ASME Certified Piping Engineer and Piping Engineering Certification from Private Training Institutes, NPTEL, and IITs. - Fundamental Subjects Addressed in Piping Design Engineering

I. Basic of Piping Systems

The fundamentals of piping systems; their function and purpose; and the many kinds of piping systems (oil, gas, steam, water, etc.)

II. Materials and Specifications for Piping

• Various pipe types (carbon steel, stainless steel, PVC, etc.)

- Material selection depending on temperature, pressure, and corrosion resistance

III. Code and Standards

Industry standards such as API, ANSI, ISO, and ASTM; ASME B31.1 (Power Piping); and ASME B31.3 (Process Piping)

IV. Piping Components:

Flexible hoses and expansion joints; pipes, fittings, valves, flanges, gaskets, and bolts.

V. Calculating Pipe Sizing and Pressure Drop

- Choosing a pipe diameter

- Calculating flow rate, velocity, and pressure loss

VI. Considerations for Piping Layout and Design

• Pipe placement in plants; - Maintenance accessibility and space optimization

VII. CAD software and 3D modeling - Practical instruction in AutoCAD, PDMS, SP3D, or PDS

VIII. Flexibility and Stress Analysis

• Thermal expansion loops and supports; stress analysis using CAESAR II

IX. Hangers and Supports for Pipes

• Various support types (variable, spring, rigid, and constant); - Calculations and placement of loads

X. Drawings and Isometrics of Piping

The P&ID (piping and instrumentation diagram) and the orthographic and isometric drawings

XI. Maintenance and Safety

Handling hazardous contaminants and managing pipeline integrity

- Software Used in Piping Design Engineering

- AutoCAD Plant 3D

- PDMS (Plant Design Management System)

- SP3D (SmartPlant 3D)

- CAESAR II (Pipe Stress Analysis)

- ANSYS (Finite Element Analysis for stress evaluation)

- Industries That Require Piping Design Engineers

- Oil & Gas

- Petrochemical

- Power Plants

- Water Treatment

- Pharmaceutical

- Construction

10. Job Roles and Salaries in Piping Design Engineering

| Job Role | Average Salary (Per Year) |

| Piping Design Engineer | $50,000 – $120,000 |

| Pipeline Engineer | $60,000 – $130,000 |

| Piping Stress Engineer | $70,000 – $150,000 |

| CAD Designer (Piping) | $40,000 – $90,000 |

- How to Pick the Best Course in Piping Design Engineering

Verify if the certification is recognized by the industry. Make sure the training involves using software. Seek out courses that involve real-world tasks.

In conclusion

A profession in piping design engineering is very fulfilling and in high demand worldwide. The skills and credentials required to enter this sector are provided by a well-structured course.